The value of surface analysis in the control of allergens

05 Apr 2020The commitment of food operators to guarantee consumer-friendly labelling is a task for various areas in the company’s business. A good management plan implies thorough knowledge of the ingredients, close cooperation with suppliers and good practices for all staff. Food preparation in shared facilities adds an extra risk factor because it is often not easy to control unwanted cross-contamination with ingredients intended for other foods. This contamination is mainly caused by 2 routes:

- Inadequate cleaning of facilities, especially surfaces that come into contact with food.

- Contamination after cleaning of these surfaces; mainly due to suspended particles or aerosols that remain in the air for some time before being deposited on work surfaces.

This cross-contamination can be controlled via two approaches with different consequences:

- Product analysis to confirm if food is free of the allergen at the end of the production process. Otherwise, preventive labelling should be implemented, although it could difficult without putting the product’s traceability at risk.

- Performing surface testing in production areas, to prevent such a problem contaminating the manufactured product.

Surface analysis recommendations:

The following key points should be taken into account for surface analysis to achieve the desired results:

- The test should be optimised for surface analysis; the procedure is not the same as that used for food analysis.

- The effectiveness of the surface cleaning protocol should be validated according to specific guideline recommendations, such as those of the Food and Drink Industry Federation, FIAB. It should also be routinely verified that these initial conditions are maintained over time.

- The best way to sample a surface is using a swab and the extraction buffer included in the kit. It is very important to use the swab provided by the manufacturer, as not all swabs are suitable. The one provided by the manufacturer must guarantee the maximum recovery of the allergen. Alternatively, if wet cleaning is performed, the rinse water can be analysed.

- Initially, a broad mapping can be done to locate “hot spots” where it is more difficult to remove residues, or unexpected sources of contamination which are common for ingredients that can be dispersed in aerosols, dust or steam. ELISA tests usually have lower detection limit than rapid strips and many samples can be analysed in a single assay. Consequently, they are very useful when initial prevention measures are putting in place in facilities where production lines are shared. Once these spots are located and tested, rapid strips can be used routinely before starting a production run or after cleaning. These analyses can be performed in as little as 10-15 minutes, allowing very quick preventive measures to be taken.

How to interpret the results to determine the level of risk in the food:

A very frequent question when interpreting a positive or negative result on a surface is to express this result in terms of the risk resulting from the presence of the allergen in the final product after production. To answer this question fully, the particularities of an industry need to be known. The procedure described below can help an operator in determining the level of risk in a particular case.

The example chosen is the determination of the presence of milk proteins on a line with a food contact surface area of 10 m2 and product production of 500 kg using the Proteon Duo Milk Express test.

A section of this surface is analysed, for example 100 cm2, following the kit protocol. The test detection limit is 0.7 µg/100 cm2*, so if the result is:

- Positive: the contamination is greater than 700 µg (0.7 mg) of milk protein in the total surface area of 10 m2.

- Negative: the allergen is present at less than 700 µg (between 0 and 0.7 mg) of milk protein in the total surface area of 10 m2.

A positive result always leads to corrective measures being taken. However, if the result is negative, the level of confidence or safety that this result gives for the final product needs to be established. Thus, dividing 0.7 mg (of allergen) by 500 kg (of product) provides the theoretical maximum amount of traces in the product. In this case, the maximum allergen present on the surface is 0.0014 mg/kg (ppm); under the most extreme assumption that 100% of the allergen ends up contaminating the product homogeneously.

This value of 0.0014 ppm is then compared with a recognized reference value. Although current legislation does not specify a maximum dose for allergens, and therefore there are no specific recommendations, data based on scientific evidence that helps is beginning to be compiled: A widely accepted model is that established by the levels in the VITAL 3.0 initiative (column 3 in the table). According to VITAL, for this specific case of milk, the minimum level of intake that can cause an allergic reaction is 0.2 mg of milk protein. If this is contained in an average 100 g portion of food, this is equivalent to a concentration of allergen in the food of 2 ppm (0.2 mg/100 g) for the contaminant to cause an adverse reaction.

Thus, comparing the VITAL 3.0 risk reference value of 2 ppm with the maximum possible amount of traces of the allergen in the food, 0.0014 ppm, it can be verified there is an assured safety level of more than 1400 times for a negative test result. Consequently, the operator can be confident of working with a very high level of safety.

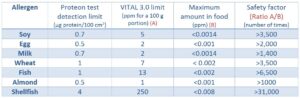

Table. Food safety level for a negative surface result.

Estimate for a surface area of 10 m2 and 500 kg of product: Test detection limit (calculated for a surface area of 100 cm2);

VITAL 3.0 limit (minimum level of intake for an allergic reaction);

Maximum amount in food (Maximum theoretical concentration of the allergen in the food for a negative surface analysis result);

Safety factor (quotient of the VITAL 3.0 limit and maximum amount expressed as a safety level multiple).

Thus, the safety level for an allergen in a production run can always be calculated by testing a certain surface area and knowing the total amount of food produced, by following the same steps as the aforementioned case. The following formula can be used as a quick calculation:

Value A= (Test detection limit) x (Total production surface area, cm2 / 100)

Value B= Value A / (total amount of food produced, kg)

Safety factor = Vital 3.0 limit / Value B

Of course, there are situations when the standard portion is different and must be taken into account; e.g. a snack may lead to an intake of 50 g of product, while breakfast with milk or a vegetable drink can be a portion of 250 g.

(*) NB. The test detection limits in the surface analysis are expressed in micrograms of allergen per unit surface area. To determine this limit accurately in a calculation, an arbitrary unit surface area of appropriate dimensions is established, e.g. 100 cm2.

At Zeulab, we have extensive experience in surface allergen analysis and can help the food industry implement control measures to prevent cross contamination with allergens. We offer an integrated solution through consulting, a mapping service by ELISA to verify the safety level of the facilities and rapid strips to quickly and easily check the cleaning process effectiveness and final product manufactured.